容积式流量计:应用与选型介绍(中英文)

什么是容积流量计

What Is Volumetric Flow Meter

容积流量计是一种能够测量在设定时间内流经测量位置的流体体积的仪器。容积式流量计作为一种机械流量计,是常见的容积流量计类型。它可以测量高粘度和腐蚀性流体的体积流量。

A volumetric flow meter is an instrument that can measure the volume of fluid passing through the measurement location within a set period of time. A positive displacement flowmeter as a mechanical flow meter is a common type of Volumetric Flow Meter. It can measure the volume flow of high viscosity and corrosive fluids.

容积式流量计的工作原理是什么?

How Does A Volumetric Flow Meter Work ?

容积式流量计是一种利用机械测量元件将流体连续分割成一个已知体积的流量计,通过反复充排流体来累积流体总量。

在给定流量计的工况下,计量空间的容积是确定的。只需测量转子的旋转次数,即可获得流经流量计的流体的累积体积。

The positive displacement flow meter is a flow meter that uses mechanical measuring elements to continuously divide the fluid into a single known volume, and repeatedly fill and discharge the volume of fluid to accumulate the total amount of fluid.

Under the conditions of a given flow meter, the volume of the metering space is determined. As long as the number of rotations of the rotor is measured, the cumulative value of the volume of fluid passing through the flow meter can be obtained.

容积式流量计的类型

Types Of Positive Displacement Flowmeter

为了满足生产中各种介质和不同工况下的流量测量需求,人们生产了各种类型的容积式流量计。其中,主要有齿轮式流量计、双转子流量计和腰轮式流量计三种类型。

1. 齿轮式容积流量计

椭圆齿轮流量计又称定排量流量计,简称PD流量计。这种流量计的壳体内装有两个转子,它们直接或间接啮合,并在流量计进出口之间的压差作用下旋转。通过齿轮的旋转,齿轮与壳体之间“计量空间”内的流体被连续排出。通过测量齿轮的转数,即可获得流经流量计的流体量。椭圆齿轮流量计测量精度高,适用于测量高粘度介质的流量,但不适用于含有固体颗粒的流体(固体颗粒会卡住齿轮,导致无法测量流量)。如果被测液体介质中含有气体,也会造成测量误差。

2. 双转子(螺杆)流量计

双转子流量计是最新一代容积式流量计,又称UF流量计或螺杆流量计。它特别适用于稀油、轻油、重油以及含砂量和含水量高的原油。被测液体的粘度范围很广。工业液体的计量流量计可现场指示,并可直接读取代码进行分发。它可以输出电脉冲信号,该信号传输至二级仪表或计算机,形成自动控制、自动检测和数据处理系统。

3. 腰轮流量计

腰轮流量计又称罗茨流量计。腰轮流量计主要用于各行业工业管道中大口径气体、液体和蒸汽介质流体的流量测量。腰轮流量计可用于各种清洁液体的流量测量,尤其适用于油品的测量,也可改装成气体流量计。其精度最高,可达0.1-0.5级。其主要缺点是:体积大、重量重、压力损失大、运行过程中振动大等。

In order to meet the requirements of various media and different working conditions for flow measurement in production, various types of positive displacement flowmeters have been produced. Among them, there are three types of gear flowmeters, dual rotor flowmeters and waist wheel flowmeters.

1. Gear Type Positive Displacement Flowmeter

Oval gear flowmeter is also called fixed displacement flowmeter, referred to as PD flowmeter. The casing of this flowmeter is equipped with two rotors, which are directly or indirectly meshed with each other, and rotate under the action of the pressure difference between the inlet and the outlet of the flowmeter. Through the rotation of the gear, the fluid filled in the “metering space” between the gear and the housing is continuously discharged. By measuring the number of rotations of the gear, the amount of fluid passing through the flowmeter can be obtained. The oval gear flowmeter has high measurement accuracy and is suitable for measuring the flow of high-viscosity media, but it is not suitable for fluids containing solid particles (solid particles will jam the gear, making it impossible to measure the flow). If the measured liquid medium contains gas, it will also cause measurement errors.

2. Double rotor (screw) flowmeter

Dual-rotameter flowmeters are the latest generation of positive displacement flowmeters, also known as UF —” flowmeters or screw flowmeters. It is especially suitable for thin oil, light oil, heavy oil, crude oil with large sand content and large water content. The viscosity range of the liquid to be measured is large. The metering flowmeter of industrial liquids can be indicated on site, and the code can be read directly and can be distributed. It can output electric pulse signal, which is transmitted to secondary instrument or computer to form automatic control, automatic detection and data processing system.

3. Waistwheel flowmeter

The waist wheel flowmeter is also called the Roots flowmeter. The waist wheel flowmeter is mainly used for the flow measurement of large-diameter gas, liquid, and steam medium fluids in industrial pipelines in various industries. The waist wheel flowmeter can be used for flow measurement of various clean liquids, especially for oil measurement, and can also be made into a flowmeter for measuring gas. Its meter has the highest accuracy, up to 0.1-0.5 level. Its main disadvantages are: large volume, heavy weight, large pressure loss, large vibration during operation, etc.

容积式流量计工作原理

VOLUMETRIC FLOW METER WORKING PRINCIPLE

容积式流量计的工作原理:

当流体流经流量计时,流量计的入口和出口之间会产生一定的压差。流量计的旋转部件(称为转子)在该压差的作用下旋转,并将流体从入口排至出口。在此过程中,流体反复填充流量计的“计量空间”,并持续地被送至出口。在给定的流量计工况下,只要测量转子的旋转次数,即可确定计量空间的容积。进而可以得到流经流量计的流体的累计容积。

椭圆齿轮流量计的工作原理:

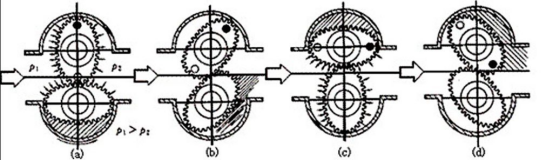

两个椭圆齿轮具有特殊的形状,相互滚动接触旋转。P1 和 P2 分别代表入口压力和出口压力。显然,P1 > P2。如图 1(a) 所示,下齿轮在两侧压差的作用下逆时针旋转,它是主动齿轮;上齿轮两侧压差相等,不产生旋转扭矩,它是从动齿轮,由下齿轮驱动顺时针旋转。如图 1(b) 所示,在压差的作用下,两个齿轮都产生旋转扭矩并继续旋转。当安装在图 1(c) 所示位置时,上齿轮成为主动齿轮,下齿轮成为从动齿轮,继续旋转至与图 1(a) 相同的位置,完成一个循环。一个循环动作会排出齿轮与壳体壁之间四个新月形腔体内的流体体积,这称为流量计的“循环容积”。

The working principle of the positive displacement flowmeter:

when the fluid passes through the flowmeter, a certain pressure difference will be generated between the inlet and outlet of the flowmeter. The rotating part of the flowmeter (referred to as the rotor) rotates under the action of this pressure difference and discharges the fluid from the inlet to the outlet. During this process, the fluid fills the “metering space” of the flowmeter again and again, and is then continuously sent to the outlet. Under the conditions of a given flow meter, the volume of the metering space is determined as long as the number of rotations of the rotor is measured. The cumulative value of the volume of fluid passing through the flowmeter can then be obtained.

The working principle of oval gear flow meter:

The two oval gears have a special shape that rolls against each other for contact rotation. P1 and p2 represent the inlet pressure and the outlet pressure, respectively. Obviously, p1>p2. The lower gear in Figure 1(a) rotates counterclockwise under the action of the pressure difference on both sides, which is the driving gear; the upper gear is equal to the pressure on both sides. No rotational torque is generated, it is a driven wheel, which is driven by the lower gear and rotates clockwise. At the position shown in Figure 1(b), both gears generate rotational torque under the action of differential pressure and continue to rotate. When it is installed in the position shown in Figure 1(c), the upper gear becomes the driving wheel, and the lower gear becomes the driven wheel, which continues to rotate to the same position as shown in Figure 1(a) to complete a cycle. One cycle action expels the fluid volume of the four crescent-shaped cavities enclosed between the gear and the housing wall, which is called the “cycle volume” of the flowmeter.

METRIC FLOW METER WORKING PRINCIPLE

椭圆齿轮流量计的工作原理是什么?

设流量计的“循环容积”为υ,在一定时间内齿轮的旋转次数为N,则该时间内流过流量计的流体容积为V,

则V=Nυ (1)

椭圆齿轮的旋转通过磁封联轴器和传动减速机构传递到计数器,直接指示流过流量计的总流量。如果加装发送装置和电子显示仪表,则远程传输只能显示瞬时流量或累计流量。

腰轮式罗茨流量计的工作原理:

腰轮式流量计又称罗茨流量计。其结构特点是:流量计壳体内有一个测量腔,测量腔内有一对或两对腰轮,可沿切线方向旋转。一对传动齿轮与两个搜索轮同轴安装在流量计外壳外部,它们相互啮合,使两个腰轮能够相互连接。流体通过侧向元件和隔板从入口流向出口,流量恒定。只需知道计量室的容积,并记录腰轮的转数 N,即可得到流经流量计的流体体积 V。显然,腰轮流量计的流量为:V=4Nv (2-2)

双转子(螺杆)流量计的工作原理:

双转子(螺杆)流量计的一对特殊齿形螺旋转子直接啮合,无相对滑动,也无同步齿轮。转子在入口和出口处的小压差驱动下旋转。因此,转子的转数与流体的累计流量成正比,转子的转速与流体的瞬时流量成正比。转子的转数通过磁耦合传递至流量计数器,从而显示流经流量计(管道)的流量。

双转子(螺杆)流量计是一种设计独特的容积式流量计,主要用于液体流量测量。

How Oval Gear Flow Meters Work ?

Let the “circulation volume” of the flowmeter be υ, and the number of gear rotations in a certain period of time is N, then the volume of fluid flowing through the flowmeter during this time is V,

Then V=Nυ (1)

The rotation of the oval gear is transmitted to the counter through the magnetic seal coupling and the transmission reduction mechanism to directly indicate the total amount flowing through the flowmeter. If the sending device is attached, and the electric display instrument is added, the remote transmission is only instantaneous flow or cumulative flow.

The working principle of the Roots flowmeter of the waist wheel flowmeter:

The waist wheel flowmeter is also called the Roots flowmeter. Its structural characteristics are: there is a measuring chamber in the shell of the flowmeter, and there are one or two pairs of waist wheels that can rotate tangentially in the measuring chamber. A pair of transmission gears are installed coaxially with the two search wheels outside the casing of the flowmeter, and they mesh with each other so that the two waist wheels can be linked with each other. There is a constant flow of fluid separated by the side and elements and sent from the inlet to the outlet. Just know the volume of the metering chamber space. And record the number of rotations of the waist wheel N. The fluid volume V through the flow basin meter can be obtained. Obviously, for the flow rate of the waist wheel flowmeter: V=4Nv (2-2)

Working principle of double rotor (screw) flowmeter:

A pair of special-toothed helical rotors of the dual-rotor (screw) flowmeter are directly meshed, without relative sliding, and without synchronizing gears. The rotor is driven to rotate by a small pressure difference at the inlet and outlet. Therefore, the number of revolutions of the rotor is proportional to the cumulative flow of the fluid, and the rotational speed of the rotor is proportional to the instantaneous flow of the fluid. The number of revolutions of the rotor is transmitted to the meter counter through the magnetic coupling, which shows the flow through the flow meter (through the pipeline).

The dual rotor (screw) flowmeter is a uniquely designed positive displacement flowmeter mainly used for liquid flow measurement.

容积式流量计适用于哪些应用?

Where Are The Positive Displacement Used For?

容积式流量计特别适用于测量粘性流体,例如油、冷凝液、树脂和液态食品。对于高粘度介质的流量,其他流量计难以测量,而容积式流量计可以精确测量,精度可达±0.2%。因此,容积式流量计常用于昂贵介质(如石油、天然气等)的总量测量。

Positive displacement flow meters are particularly suitable for the flow of viscous fluids such as oil, condensate, resins and liquid foods. For the flow of high viscosity medium, other flowmeters are difficult to measure, but positive displacement flowmeters can accurately measure the accuracy of ±0.2%. Therefore, positive displacement flowmeters are often used in the total measurement of expensive media (oil, natural gas, etc.).

容积式流量计的应用

POSITIVE DISPLACEMENT VOLUMETRICFLOW METER APPLICATION

容积式流量计的应用:

容积式流量计、差压式流量计和浮球式流量计是应用最广泛的三种流量计,常用于昂贵介质(如石油、天然气等)的总量计量。

常用的容积式流量计包括椭圆齿轮流量计、双转子流量计和腰轮式流量计。

椭圆齿轮流量计的应用:

椭圆齿轮流量计(又称位移流量计、齿轮流量计)是一种容积式流量计,也是一种高精度流量计。椭圆齿轮流量计可采用不同材料(如铸铁、铸钢、304不锈钢、316不锈钢)制造,用于精确测量管道中液体的连续或间歇流量或瞬时流量。椭圆齿轮流量计特别适用于重油、聚乙烯醇、树脂等高粘度介质的流量测量,例如化工、石油、制药、电力、冶金和食品等行业的流量测量。

双转子流量计的应用:

双转子流量计属于世界上最新一代容积式流量计,也称为UF-‖流量计或螺旋流量计。双转子流量计是一种用于测量和控制管道内液体流量的精密仪器。广泛应用于石油、化工、冶金、电力、交通运输、船舶、油库、码头、罐车等部门,尤其适用于原油、成品油、轻烃等工业液体的流量测量。该流量计可现场显示流量,并可直接读取字码。它还可以配备变送器输出电脉冲信号,并将信号传输至二级仪表或计算机,形成自动控制、自动检测和数据处理系统。

腰轮流量计的应用:

腰轮流量计又称罗茨流量计,主要用于各行业工业管道中大口径气体、液体和蒸汽介质流体的流量测量。腰轮流量计也可用于各种清洁液体的流量测量,尤其适用于油品的流量测量,也可改装成气体流量计。其精度极高,可达0.1-0.5级。腰轮流量计主要应用于石油化工行业、油库、平台、码头、水气站等场所的装卸、运输、油品销售计量、定量交付、原材料进出计量、燃料消耗量等。

Application of positive displacement flowmeter:

Positive displacement flowmeter, differential pressure flowmeter and float flowmeter are listed as the three most widely used flowmeters, and are often used in the total measurement of expensive media (oil, natural gas, etc.).

Commonly used volumetric flowmeters include oval gear flowmeters, dual rotor flowmeters, and waist wheel flowmeters.

Applications of oval gear flowmeters:

Oval gear flowmeter (also known as displacement flowmeter, gear flowmeter) is a kind of positive displacement flowmeter, and it is a kind of high precision flowmeter. The oval gear flowmeter can be made of different materials (cast iron, cast steel, 304 stainless steel, 316 stainless steel) for precise continuous or intermittent measurement of liquid flow or instantaneous flow in pipelines. The oval gear flowmeter is especially suitable for flow measurement of heavy oil, polyvinyl alcohol, resin and other media with higher viscosity, such as flow measurement in chemical, petroleum, pharmaceutical, electric power, metallurgy and food industries.

Application of dual rotor flowmeter:

The dual-rotor flowmeter belongs to the latest generation of positive displacement flowmeters in the world, also known as UF-‖ flowmeters or screw flowmeters. Double rotameter is a precision instrument for the measurement and control of liquid flow in pipelines. Widely used in petroleum, chemical, metallurgy, electric power, transportation, ships, oil depots, terminals, tank trucks and other departments, especially for crude oil, refined oil, light hydrocarbons and other industrial liquids. The metering flowmeter can indicate on-site, and the word code can be read directly and It can be equipped with a transmitter to output electrical pulse signals, which can be transmitted to secondary instruments or computers to form automatic control, automatic detection and data processing systems.

Application of waist wheel flowmeter:

The waist wheel flowmeter is also called the Roots flowmeter. The waist wheel flowmeter is mainly used for the flow measurement of large-diameter gas, liquid, and steam medium fluids in industrial pipelines in various industries. The waist wheel flowmeter can be used for flow measurement of various clean liquids, especially for oil measurement, and can also be made into a flowmeter for measuring gas. Its meter has the highest accuracy, up to 0.1-0.5 level. The waist wheel flowmeter is mainly used in the petroleum and petrochemical industry, oil depot oil platform, wharf, water gas station for loading, shipping, oil sales measurement, quantitative delivery, raw material in and out measurement, fuel consumption, etc.

如何选择合适的容积式流量计?

How To Choose The Right Positive Displacement Flowmeter?

容积式流量计性能选择

选择容积式流量计时应考虑以下五个要素:(1)流量范围;(2)被测介质的物理特性;(3)测量精度;(4)耐压(工作压力)和压降;(5)用途。

(1)流量范围

容积式流量计的流量范围与被测介质的类型(主要取决于流体的粘度)、使用特性(连续工作或间歇工作)、测量精度等因素有关。

(2)被测介质的物理特性

被测介质的物理特性主要考虑流体的粘度和腐蚀性。

(3)测量精度

容积式流量计是目前测量精度最高的流量计之一。

现场条件对测量精度的主要影响因素是被测介质的粘度和温度。

(4)耐压性(工作压力)和压力损失

流量计的工作压力应由流量计壳体承受。不同材质的压力部件应采用不同的工作压力要求,以避免不安全使用。

(5)使用目的

用于计量和计费的流量计主要考虑其测量精度,可作为现场指示仪表;用于过程控制的流量计主要考虑其可靠性,应配备变送器、计数器、调节和显示仪表等各种配套设备。

Choice of Positive Displacement Flowmeter Performance

The following five elements should be considered in the performance selection of positive displacement flowmeter: (1) flow range; (2) physical properties of the measured medium; (3) measurement accuracy; (4) pressure resistance (working pressure) and pressure loss; (5) purpose of use.

⑴ flow range

The flow range of the positive displacement flowmeter is related to the type of the measured medium (mainly determined by the viscosity of the fluid), the characteristics of use (continuous work or intermittent work), measurement accuracy and other factors.

(2) Physical properties of the measured medium

The physical properties of the measured medium mainly consider the viscosity and corrosiveness of the fluid.

⑶ measurement accuracy

Positive displacement flowmeter is one of the flowmeters with the highest measurement accuracy at present.

The major influences of site conditions on the measurement accuracy are the influence of the viscosity of the measured medium and the influence of temperature.

⑷ Pressure resistance (working pressure) and pressure loss

The working pressure of the flowmeter should be endured by the flowmeter shell. Different requirements for the working pressure should be used for pressure components of different materials to avoid unsafe use.

⑸ Purpose of use

The flowmeter used for measurement and accounting mainly considers its measurement accuracy, which can be an on-site indicating instrument; the flowmeter used for process control mainly considers its reliability, and should have various supporting equipment such as transmitters, counters, adjustment and display instruments, etc. .

声明:

-文章转载自SENTEC,由爱泽工业翻译,如有侵权,请联系删除!

-如有偏颇,欢迎指正!

下一篇:潜水泵综合指南(中英文)

沪公网安备31011002006738号

沪公网安备31011002006738号