液压泵发出异常噪音的原因分析(中英文)

每个人都喜欢安静的泵——它只是在工作,不会经常发生故障。虽然噪音大的泵通常归因于气蚀,但并非所有异常噪音都表明泵存在此问题。轴承故障、流动湍流、再循环,甚至机器的机械或电气几何形状都会产生噪音。

说到液压泵,了解不同噪音的含义是有益的。通过练习,可以学会区分正常的运行声音和故障迹象。

液压泵噪音过大或不稳定是故障的征兆,如果不迅速正确地处理,可能会导致损坏或加速磨损。虽然听到泵发出奇怪的声音总是令人担忧,但确定哪些噪音与不同的故障有关可以表明问题的根源,并提供机会在发生重大损坏之前修复设备。

Everybody likes a quiet pump – it just does its job and doesn’t break down often. Although a noisy pump is often attributed to cavitation, not every abnormal noise suggests a pump is suffering from this problem. Failing bearings, flow turbulence, recirculation, and even a machine’s mechanical or electrical geometry can generate noise.

When it comes to hydraulic pumps, it pays to know what different noises mean. With practice you can learn to distinguish between the normal operating sounds and the signs that something is wrong.

Excessive or erratic hydraulic pump noise is a symptom of malfunction that could cause damage or accelerated wear if not addressed quickly and correctly. While it’s always alarming to hear strange noises emitted from your pump, determining which noises are related to different faults can indicate the root of your problem and provide the opportunity to repair the equipment before major damage occurs.

1. 曝气/Aeration

当空气污染液压油时就会发生曝气。液压油中的空气在系统中循环,压缩和减压时会发出令人震惊的撞击声或敲击声。空气泄漏引起的呜呜声类似于气蚀,但由于液压系统中空气分布不均匀,其性质更加不稳定。

空气通常通过泵的入口进入液压系统。因此,确保泵进气管路状况良好并且所有夹具和配件都拧紧非常重要。还可以检查储液罐中的液位,如果液位低,请将其加注到正确液位。在某些系统中,空气可以通过泵的轴封进入泵,因此还建议检查泵轴封的状况。

Aeration occurs when air contaminates the hydraulic fluid. Air in the hydraulic fluid makes an alarming banging or knocking noise when it compresses and decompresses, as it circulates through the system. The whining noise caused by air leaks is similar to cavitation, but is more erratic in nature due to the uneven distribution of the air in the hydraulic system.

Air usually enters the hydraulic system through the pump’s inlet. For this reason, it is important to make sure pump intake lines are in good condition and all clamps and fittings are tight. You could also check the fluid level in the reservoir, and if low fill to the correct level. In some systems air can enter the pump through its shaft seal, so checking the condition of the pump shaft seal would also be recommended.

2. 气蚀/Cavitation

巨大的呜呜声或刺耳噪音(或在极端条件下发出剧烈的咔哒声)可能表明存在气蚀。气蚀会导致金属部件腐蚀。系统中产生的金属碎片会加速下游部件的磨损。在某些情况下,气蚀会导致不同部件的机械故障。

当液压油需求未得到满足时,就会发生气蚀。虽然气蚀可能发生在液压回路的任何地方,但它通常发生在泵上。可能发生气蚀的其他区域包括流体管路堵塞、流体过滤器堵塞、油粘度过高和泵转速过高。

A loud whining or screeching noise (or, in extreme conditions, a severe rattling sound) can be indicative of cavitation. Cavitation results in the erosion of metal components. The resulting metal debris in the system accelerates the wear of components located down the stream. In some cases, cavitation can lead to mechanical failure of different components.

Cavitation occurs when demand for hydraulic fluid is not being met. While cavitation can occur just about anywhere within a hydraulic circuit, it commonly occurs at the pump. Other areas where cavitation may occur include fluid line blockages, blocked fluid filters, overly high oil viscosity and excessive pump rotation speed.

3. 泄压阀设置/Relief valve settings

啸叫声或不规则的嘶嘶声通常表明泄压阀调节不当或卡在打开状态。好的经验法则是,如果声音不对,那很可能就是有问题。执行器猛击、失速和过热是这些阀门出现问题的早期症状。

A whistling sound or erratic hissing often suggests that a relief valve is improperly adjusted or stuck open. A good rule of thumb is if it doesn't sound right, it probably isn't. Slamming of actuators, stalls and excessive heat generation are the early symptoms of problems with these valves.

4. 方向阀阀芯移位/Directional valves spool shift

在大多数情况下,方向阀在非常安静的机器上只会发出微弱的“咔嗒”声。如果能听到方向阀阀芯移位的声音,则很可能存在问题。

如果两级方向阀上的先导阻风门调节不当,则在移位时会发出砰砰的声音。阀芯很容易损坏,阀芯的突然移动会在整个机器中引起震动,这意味着系统的薄弱点将受到影响。在这种情况下,需要调节先导阻风门,以使阀芯平稳移位并延长部件的使用寿命。

For the most part, directional valves should create no more than a faint "click" on very quiet machines. If you can hear a directional valve spool shift, chances are there could be a problem.

If the pilot chokes are improperly adjusted on a two-stage directional valve, it will audibly slam when it shifts. The spool can easily be damaged, and sudden movement of the valve spool causes shock throughout the machine, meaning the weaker points of the system will suffer. In this instance the pilot choke will need to be adjusted for smooth shifting of the spool and improved component longevity.

5. 气缸卡住或打滑/Cylinders binding or slipping

同样,气缸也应几乎没有噪音地移动。如果气缸发出噪音,则可能是卡住或打滑。弯曲的连杆会磨损密封件,而打滑会降低机器的性能,将磨损的密封件中的污染物传送到其他部件。应尽快检查有噪音的气缸。

Likewise, cylinders should also move with almost no noise. If a cylinder is creating noise, it may be binding or slipping. A bent rod will wear seals and slippage degrades the performance of the machine, sending contaminants from the resulting worn out seals to other components. A noisy cylinder should be investigated as soon as possible.

6. 其他机械故障/Other mechanical malfunctions:

研磨声、呼呼声、轰鸣声、咔哒声或一般的噪音都表明存在某种机械故障。特别是,研磨、刮擦或粗糙运行表明内部磨损严重。

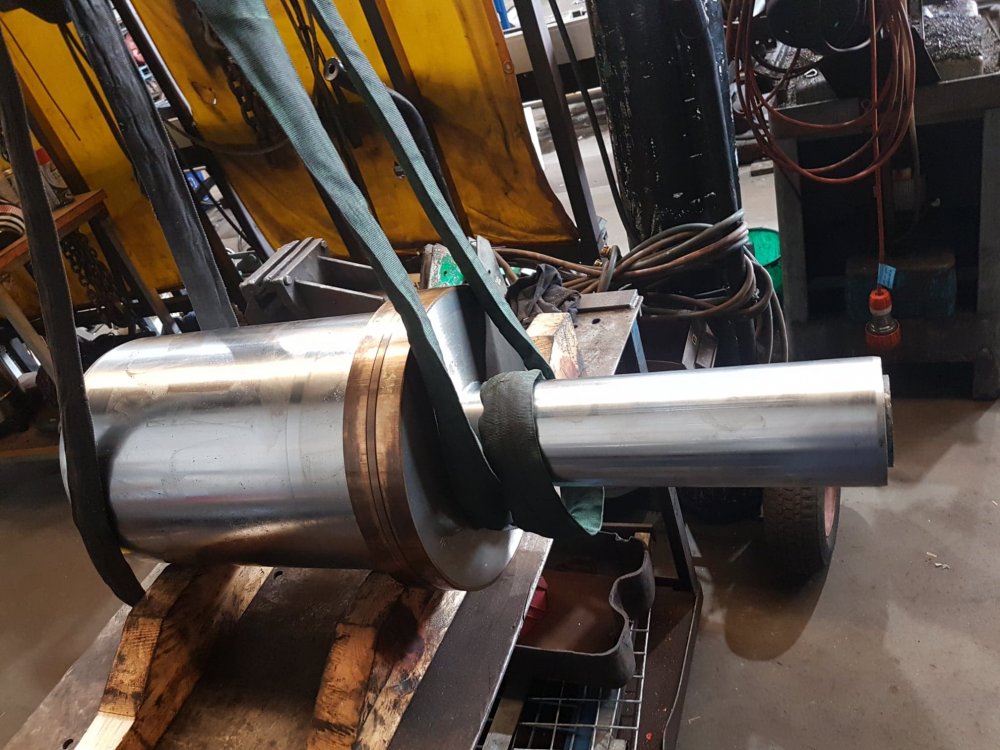

在这种情况下,应由经过培训的技术人员拆卸、检查和检修泵。可以更换磨损的部件,在某些情况下,还可以进行机械加工以恢复泵表面。

Grinding sounds, whirring, roaring, rattling or general noisy operation all suggest some type of mechanical malfunction. In particular, grinding, scraping or rough running is an indication of serious internal wear.

In such cases, the pump should be disassembled, inspected and overhauled by a trained technician. Worn components may be replaced, and in some instances, machining work performed to restore the pump surfaces.

仅凭声音就足以排除故障吗?

Is sound alone enough to troubleshoot?

噪音问题只是表明液压设备可能出现故障的一个迹象。还有其他几种必要的故障排除方法来确定泵的问题所在,包括监测热量问题、压力问题和流量问题。

虽然仅凭声音无法诊断机器的问题,但聆听机器发出的声音可以带来巨大的回报,因为它可以在问题导致昂贵的组件故障和液压设备意外停机之前尽早发现问题。

Noise issues provide just one indication of what might be wrong with your hydraulic equipment. There are several other troubleshooting methods necessary to identify what is wrong with your pump, including monitoring for heat problems, pressure problems and flow problems.

While sound alone will not diagnose the problem with your machine, listening to the sounds it makes can pay off in large dividends by catching problems early before they lead to costly component failures and unscheduled downtime of hydraulic equipment.

声明:

- 文章转载自网络,由爱泽工业翻译,如有侵权,请联系删除!

- 如有偏颇,欢迎指正!

沪公网安备31011002006738号

沪公网安备31011002006738号